Food-to-Feed Quality Programme

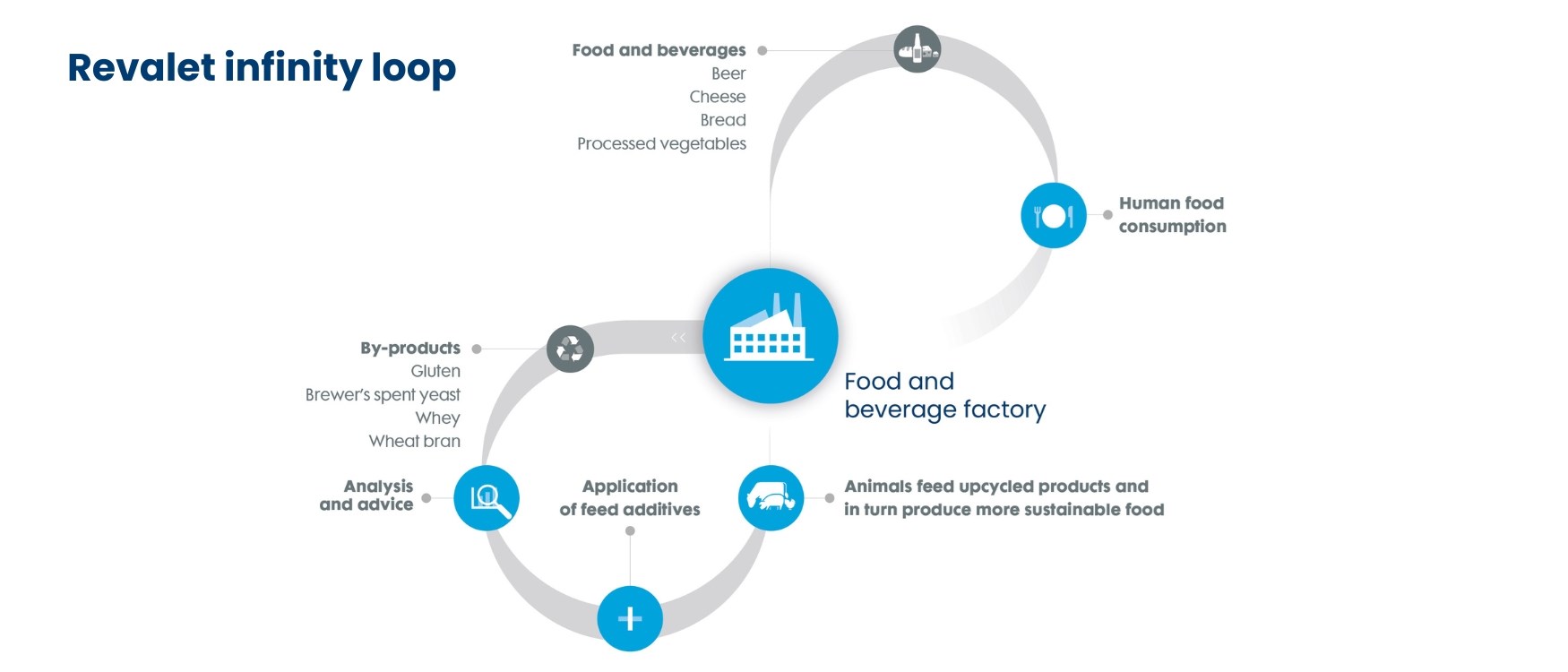

With the world population growing rapidly, and raw materials becoming scarcer, treating by-products from the food and beverage industry as a viable, nutritious source of energy for animals is gaining attention. However, preserving by-products for this use can present multiple challenges, which means that significant volumes still end up as landfill waste or in biogas production. Since raw materials and final feeds need to provide stable levels of nutritional, the demand for ways to effectively preserve the nutritional quality of food by-products for use in feed continues to increase.

Reducing food waste – a critical opportunity of size and scale

Even as efforts to increase feed production are driving the development of alternative proteins, such as insect meal and single-cell proteins, a tremendous amount of food produced is wasted each year. According to the UN’s Food and Agriculture Organization, one-third of food produced – or about 1.3 billion tons – is lost in the food chain. And some estimates are even higher.

Beyond the economic costs, it’s important to consider the systemic environmental and energy costs associated with waste in the supply chain. Globally, about 60% of food grown on the planet is not of a quality suitable for human consumption. Fortunately, science has found a way to use crop by-products as purposeful components in the food chain. For example, portions of the maize plant that cannot be digested by humans can be fed to dairy cows and other ruminants.

Efforts are underway to identify more repurposing options for feed and food by-products. For example, brewer's yeast is naturally high in protein and could possibly replace parts of the animal feed ingredients that require arable land to produce.

Paving the road to effective solutions

There is no silver bullet solution to preserve by-products from food and beverage production. That’s why it's important for food and beverage processors to build strong partnerships and make powerful connections – not only with our Selko experts, but also with feed and farm industry partners who can become valued customers in turning your waste into profit. Selko has a vast network of feed processors and farmers across the globe, as well as experience in closing the gap and acting as a bridge between you and the animal protein industry.

Whether you are exploring possibilities to move waste streams into feed ingredients or have already started and are looking for better preservation and more stable and dry matter supply, Selko can support you in reaching your sustainability and economic goals.

Our Revalet line of powerful preservation products

Selko developed Revalet to help to maintain the nutritional value and dry matter levels of by-products. The Revalet range of products is based on synergistic blends of organic acids and surfactants that are formulated to reduce moulds, yeasts and Enterobacteria in by-products. Our latest innovation, Revalet Super, includes agents that destabilise yeast cell walls in order to enhance antimicrobial efficacy at low dosages.

Our teams will carefully evaluate each challenge your plant faces, to determine which Selko product will provide the most cost-effective solution, how to apply products safely and effectively, and at what point in the process these solutions can be applied.

Serving you with our expertise and collaboration support

Determining the right inclusion rate

Typically, our representatives will visit your plant to evaluate the best possible solution with you. Since microbes, especially yeasts, can grow rapidly and deteriorate by-product quality, early preservation is vital to maintain dry matter and nutritional value. We take samples and preserve them on the spot. This allows you to witness the preservation step and ensures our analysis provides a reliable result after the standard storage time, since the nutritional value is preserved at the source.

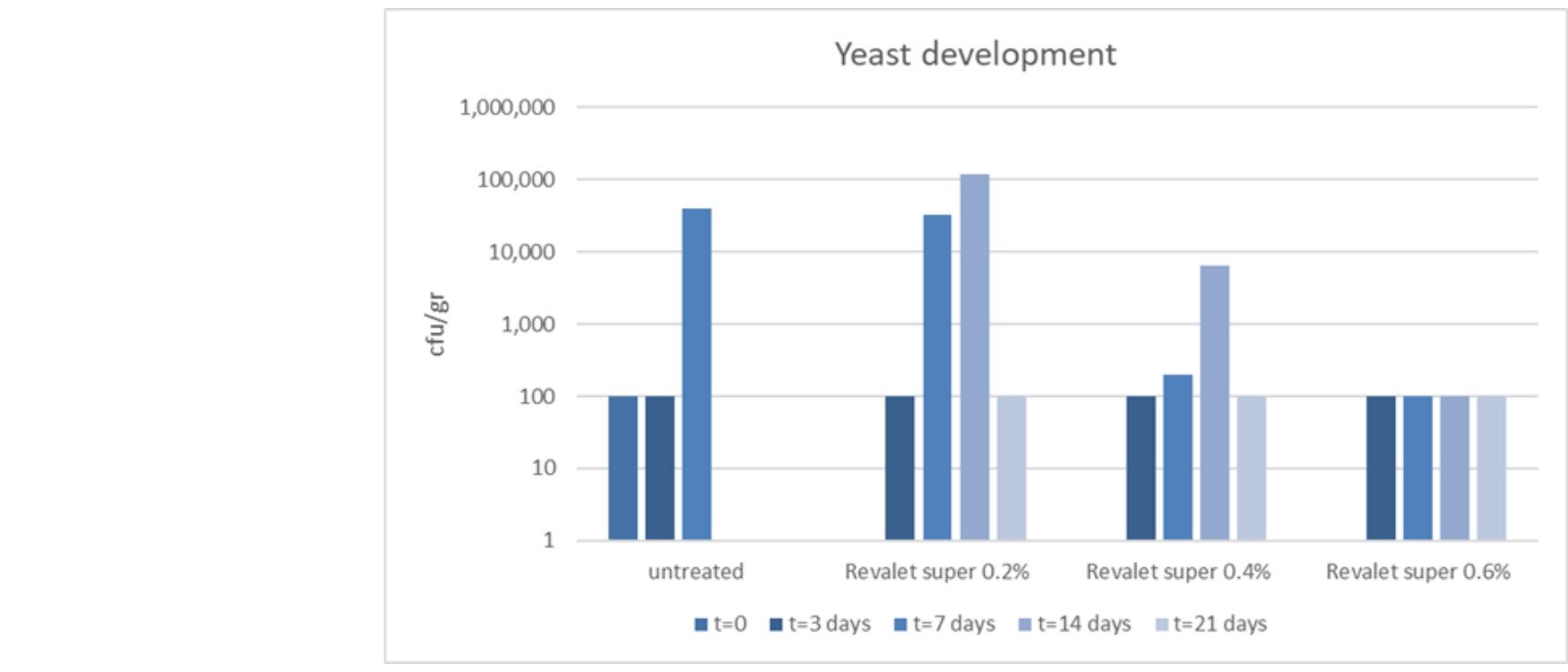

Applying various inclusion rates on the samples allows us to pinpoint the most cost-effective solution. We will analyse the samples at Masterlab and report the results back to you.

Dose response test for Revalet Super.

Dose response testing confirmed the most cost-effective solution. After day 7 the control sample was deemed unfit for feeding due to pungent smell, indicating complete microbial wastage. Therefore, it was taken out of the study.

Providing safe, accurate and reliable dosing

Once the Revalet inclusion rate is determined, it is important to make sure the products are applied safely and accurately. Accurate dosing and application processes within the food processing installation are essential to ensure product efficacy. Selko's dosing and application services are value-added components included in the programme and can be fully automated and integrated in the processing lines.

Selko's state-of-the-art dosing systems allow for even distribution of Revalet products and can be incorporated into processing systems for data gathering and performance tracking.

Supporting collaboration across the supply chain

Disruptions in the supply chain are creating a heightened sense of urgency when it comes to figuring out how the industry can safely and efficiently use feed and food by-products to offer a wider range of options for feed ingredients. Using by-products in feed also brings sustainability benefits.

Since food and beverage production takes place all over the world, by-products can often be sourced locally, reducing the need for long distance transport or energy consuming drying processes. For example, in the Netherlands, 5.4 million tons of liquid and moist by-products were used by home mixing farms in 2021, roughly equal to 1.25 million tons of dry feed materials (Source: Circular Feed Association).

We believe that feed-to-food safety and sustainability demand a collaborative approach involving partners across the supply chain. We are committed to connecting the food- and beverage industry with the animal industry, in order to create powerful, long-lasting partnerships that lead to more resilient and sustainable food systems and bring a new, circular direction to Feeding the Future. We will help you put in place an integrated model tailored to the challenges at each critical control point, to ensure you have a holistic strategy to produce safe food through environmentally responsible production.